Singapore Chirotherapy: Spinal Care Solutions

Across Singapore, chirotherapy provides practical ways to reduce pain and improve function without surgery. Elite Spine Centres in Singapore promotes a whole-person method that seeks maximal pain reduction by addressing underlying drivers. Their model combines hands-on https://www.chirotherapy.com.sg/ care with advanced therapies and individualized rehabilitation plans.

Founded by Dr. Michael Bryant, Elite Spine Centres positions spinal care Singapore as an affordable, safer choice relative to injections, long-term drugs, or surgery. Clinics feature best-practice protocols, modern devices, and outcome-focused pathways that restore function and improve spinal health progressively.

This article examines the workings of chirotherapy in Singapore, what patients can expect, and why Elite Spine Centres is frequently noted as one of conservative care providers. We will cover techniques, outcomes, safety, costs, and access so readers can choose confidently about non-invasive spinal treatment options in Singapore.

Key Takeaways

- Chirotherapy Singapore provides a whole-person, non-invasive spinal treatment focused on sustained relief.

- Elite Spine Centres integrates chiropractic Singapore techniques with advanced therapeutic technology.

- Dr. Michael Bryant leads a model prioritizing pain reduction and functional gains.

- Services are promoted as affordable alternatives to surgery and ongoing injections.

- Expect personalized rehabilitation and results-focused care for lasting spinal health.

Chirotherapy Explained: How It Compares to Conventional Care

Chirotherapy is a individualized approach that blends hands-on manual care with rehabilitative exercises and modern therapeutic tools. This form of spine and joint care restores joint mechanics, lower pain, and enhance movement quality. Practitioners assess posture, spinal alignment, soft tissue health, and nervous system function to design individualized protocols.

Core Principles & Definition

At its core, chirotherapy targets mechanical dysfunctions that contribute to symptoms. Treatment options include specific spinal corrections, soft tissue mobilization, targeted exercise progressions, and guided home programs. The goal is to treat root causes rather than simply mask pain, making it a preferred conservative spinal treatment.

Whole-Body Focus: MSK & Nervous System

This approach recognizes whole-system links where the spine and joints influence nerve signaling, posture, and movement. By resolving joint restriction, muscle imbalance, and nerve irritation, chirotherapy supports optimized nervous system performance. The result can be better function, reduced pain, and a reduced need for invasive procedures.

How chirotherapy complements or differs from physiotherapy and medical interventions

In the debate of physiotherapy vs chirotherapy, both disciplines share common ground in exercise prescription and functional rehabilitation. Chirotherapy often emphasizes spinal adjustments and manual correction alongside technology such as low level laser therapy and decompression, offering a broader set of conservative spinal treatment options. Physiotherapy often centers on graded exercise, movement retraining, and electrotherapies.

Chirotherapy can complement medical care when imaging or medications are needed. It can also reduce the need for surgery by delivering integrated, non-surgical care that combines manual techniques with technology-assisted therapies like shockwave and electromagnetic therapy. Patients in Singapore increasingly opt for this integrated path for effective, conservative spinal treatment and holistic neuromusculoskeletal care.

Chirotherapy Singapore: Why Patients Choose Elite Spine Centres

Patients prefer Elite Spine Centres Singapore for focused care that seek to correct the root of pain rather than cover discomfort. The clinic integrates hands-on treatment, technology and guided rehabilitation into programs tailored for each person. Comfortable facilities, modern equipment and a team approach help deliver consistent results across common spinal and joint complaints.

Signature Functional Correction Method (FCM) is the clinic’s flagship method. The Functional Correction Method creates a stepwise plan that combines chiropractic adjustments, soft tissue therapy, conservative modalities and progressive exercises. This method targets biomechanical correction and nervous system balance while lowering pain and boosting function.

Inside the FCM Approach

FCM applies manual techniques and rehab to resolve chronic strain patterns. Therapies such as decompression, low level laser and shockwave are incorporated when needed to enhance progress. Treatment plans include at-home routines and lifestyle coaching to support long-term change.

Experienced clinicians and founder credentials

Clinicians at the centre are trained in advanced chiropractic care and therapeutic technology. The programme was developed by Dr Michael Bryant chiropractor, a Doctor of Chiropractic from the United States and a certified member of the Alliance of Chiropractic. The team’s combined clinical experience supports targeted treatment for complex neck and back issues.

Patient testimonials and local reputation in Singapore

Patient reviews Singapore report consistent pain reduction, better movement and posture correction. Reviewers frequently praise clinicians by name, noting thorough education, supportive teams and useful homework routines. Local trust underpins a strong reputation for effective, conservative spinal care.

| Feature | What it Offers | Why It Helps |

|---|---|---|

| Functional Correction Method | Integrated manual care, tech therapies, rehab and lifestyle plans | Targets root causes, reduces recurrence |

| Experienced Team | Chiropractors with advanced training and credentials | Confident diagnosis and tailored treatment |

| Advanced Modalities | Modern devices paired with manual treatment | Faster pain relief and tissue healing |

| Patient Support | Home exercise programs, posture coaching, follow-up | Long-term improvement and self-management |

Conditions Chirotherapy Commonly Treats

Chirotherapy helps with a broad range of spine-related and nerve-related conditions seen in Singapore clinics. Patients come for focused treatment that combines spinal correction, soft tissue work, and rehabilitative exercises to improve movement, lower discomfort, and rebuild functional capacity.

Below is an overview of frequent issues and how conservative care may help.

Back and neck pain

Persistent low back or neck pain often stems from mechanical stress, disc wear, or poor posture. For patients facing herniated discs, Singapore non-surgical slipped disc treatment offers methods such as spinal decompression, gentle manipulation, and progressive rehabilitation to decompress affected tissues and improve daily function.

Sciatica and nerve-related symptoms

Radicular pain, numbness, tingling, and weakness along a nerve pathway are common triggers for visits. sciatica chiropractic approaches focus on relieving nerve irritation through targeted adjustments, traction, and soft tissue release. These methods aim to ease inflammation and restore nerve glide without immediate resort to surgery.

Shoulder pain and joint problems

Shoulder discomfort can arise from rotator cuff strains, joint degeneration, or sporting injuries. shoulder pain chiropractic Singapore pairs joint mobilization, myofascial techniques, and exercise progression to increase ROM and reduce pain during daily tasks and training.

Headaches, posture issues, and pediatric concerns

Cervicogenic headaches and migraine-like pain may be associated with upper neck dysfunction. Posture-related aches from sedentary work respond to corrective strategies that restore spinal balance. Gentle pediatric adjustments can help with conditions such as infant colic and feeding difficulties by correcting gentle mechanical issues.

| Issue | What You May Feel | Chirotherapy Approaches | Expected Goals |

|---|---|---|---|

| Herniated / Degenerative Discs | Back/neck pain with possible limb radiation, stiffness | Spinal decompression, targeted manipulation, graded exercises | Reduce nerve pressure, improve mobility, avoid surgery when possible |

| Sciatica / Radiculopathy | Radiating pain with sensory changes or weakness | Mobilization, neural gliding, anti-inflammatory modalities | Reduce leg pain, normalize nerve mechanics |

| Shoulder Injuries & Osteoarthritis | Limited overhead use, stiffness, weakness | Manual therapy plus staged strengthening | Restore range, reduce pain, improve functional use |

| Headaches & Postural Pain | Headaches with neck/upper-back tension | Cervical correction, posture retraining, ergonomic advice | Reduced frequency, better posture, higher daily comfort |

| Pediatric Concerns (e.g., Infant Colic) | Feeding/sleep issues, irritability | Very light techniques with caregiver coaching | Calmer behavior, better feeding and sleep |

Clinics in Singapore individualize care. When conservative strategies target the underlying mechanics and tissue healing, many patients see meaningful gains in pain reduction and daily performance.

Signature Treatments and Advanced Therapeutic Technologies

Elite spine centres in Singapore blend manual care with targeted technologies to accelerate progress and reduce pain. Patients often receive tailored plans that mix hands-on correction, rehabilitation exercises, and device-led therapies to address disc, nerve, and soft tissue problems.

Spinal decompression offers a non-surgical path for chronic back and neck pain. The technique uses controlled traction to reduce disc stress and nerve compression. Clinics across Singapore report improved pain scores and better function for patients who tried Singapore spinal decompression after conservative care plateaued.

Low level laser techniques reduce inflammation and speed healing by delivering precise light wavelengths to injured tissues. Cold laser sessions can shorten recovery times for sprains, tendon injuries, and post-treatment swelling. Many rehabilitation packages list Singapore cold laser therapy as a component to support tissue repair and comfort.

Radial shockwave treatment generates rapid mechanical impulses to encourage circulation and remodel stubborn tissue. The method works well for tendinopathies, plantar fasciitis, and persistent muscle trigger points. Therapists often combine shockwave therapy Singapore with stretching and strength work to boost results.

Super Inductive System SIS uses focused electromagnetic stimulation to target deeper muscle and nerve structures. Clinicians use SIS for neuromuscular activation, pain modulation, and to support fracture and soft tissue healing. When combined with exercise and manual therapy, Super Inductive System SIS can shorten rehabilitation timelines and enhance function.

Many clinics build multimodal plans that link decompression, low level laser, shockwave therapy Singapore, and Super Inductive System SIS. This integrated strategy aims to relieve pain quickly, rebuild tissue resilience, and reduce the need for invasive procedures.

Rehabilitation, Exercise and Long-Term Recovery Strategies

A structured rehabilitation plan connects in-clinic work to everyday living. Clinics in Singapore layer manual therapy with progressive exercise to restore capacity, mobility, and confidence. That blend speeds recovery and reduces the chance of repeat injury.

Customized Programs & Daily Work

Clinicians craft one-on-one programs based on movement tests, imaging and goals. Each plan includes clear progressions, milestones and therapist-led sessions.

Patients are given focused home exercises for back pain to maintain improvements between appointments. Regular completion of these “homework” tasks correlates with better outcomes and fewer follow-ups.

Soft-Tissue Care, Sports Massage & Stretching

Doctor-directed soft tissue mobilization reduces adhesions and calms protective tightness. Therapists combine hands-on release with active stretches to restore range of motion.

Sports massage Singapore supports quicker turnaround and tissue conditioning. When paired with stretch therapy, the result is improved flexibility and less pain during activity.

Ergonomics and Postural Re-Education

Therapists give practical tips on ergonomics, sleep positions and training loads to protect healing tissues. Small daily changes reduce flare likelihood and support long-term progress.

Posture correction Singapore programs teach movement patterns that restore normal biomechanics. The goal is independence, so patients can confidently care for their spine health.

| Rehab Component | Purpose | What’s Included |

|---|---|---|

| Individualized exercise plan | Strengthen weak links, retrain movement | Progressive resistance, balance drills, functional tasks |

| Home exercises back pain | Sustain gains daily | Daily mobility sets, core activation, pain-relief routines |

| Soft tissue mobilization | Ease tightness and stiffness | Instrument-assisted release, manual therapy, myofascial release |

| Sports massage Singapore | Enhance recovery for athletes | Deep tissue work, trigger point release, pre/post-event care |

| Posture correction Singapore | Restore biomechanics and prevent relapse | Postural drills, ergonomic changes, movement cueing |

Assessment, Diagnostics and Personalized Care Pathways

Initial visits set the tone for tailored care. A doctor consult integrates clinical history with a focused physical exam to map pain patterns, range of motion and functional limits. New patient promotions often bundle initial sessions, covering consult, exam and a recommended plan of care.

What Happens at the First Visits

The doctor performs hands-on testing, neurological screening and movement analysis to pinpoint contributing factors. Objective measures inform outcome targets and determine which manual techniques and technologies fit best.

Functional assessment FCM is used to evaluate control and movement quality. Scores determine staged progressions that balances hands-on care with rehabilitative exercise and lifestyle advice.

Imaging Review & Tailored Planning

When available, clinicians review imaging to confirm or rule out structural changes. An X-ray MRI review chiropractic session aligns imaging with clinical signs and rules out red flags. Clinics frequently offer a follow-up consult to discuss imaging results and refine the plan.

Imaging informs the choice and timing of interventions, from decompression to soft tissue work, while preserving a individualized focus on function and quality of life.

FCM: Techniques, Technology & Tracking

The Signature Functional Correction Method blends manual adjustments, soft tissue release and targeted therapies. Treatments may include spinal decompression, Super Inductive System, low level laser therapy, shockwave and EMS in a sequenced sequence.

Each phase sets metrics and schedules reviews. Outcome tracking captures pain, mobility and function to steer progression and limit recurrence.

| Assessment Element | What It Shows | Typical Next Step |

|---|---|---|

| Doctor consult & physical exam | Pain sources, motion limits, neuro findings | Personalized treatment plan and home exercise prescription |

| Functional assessment FCM | Movement quality, stability, rehab staging | Sequenced care with metrics |

| X-ray MRI review chiropractic | Alignment and disc status, structural notes | Refined plan and selected modalities |

| Outcome tracking | Pain scores, range of motion, functional milestones | Regular reviews and plan tuning |

Cost, Access and New Patient Offers in Singapore

Finding transparent prices and simple access helps people get started with minimal risk. Clinics in Singapore often offer intro specials to lower the barrier for first visits. These offers help patients compare chiropractic cost Singapore and weigh non-surgical options before deciding on longer programs.

Many clinics run a new patient chiropractic special to welcome first-timers. A typical example lists a package at $88 (regular $248) that includes two sessions. The bundle usually includes a doctor consult and exam, doctor-directed soft tissue mobilization, ATT-300 roller massage bed use, free follow-up consult plus X-ray/MRI review as applicable, and one bonus therapy chosen by the doctor such as shockwave, cold laser, EMS, or SIS.

Other promotions can be more budget-friendly. One common promotion offers a $58 professional consult and treatment with two bonus therapies added. Online booking is required to secure these promo prices in many clinics.

Value proposition

Conservative care promotes Singapore non-surgical back pain treatment as a safer alternative to injections, drugs, and operations. Clinics highlight cost savings versus invasive procedures when discussing local chiropractic cost. The clinical aim is symptom relief and function restoration while minimizing procedural risk.

The real value shows up for patients who prefer targeted manual therapy, device-based care and exercise-based rehab before more aggressive steps. This approach often lowers future medical costs when successful.

Clinic access and patient experience

Clinics often operate at several Singapore locations with clean, modern spaces and friendly front-desk teams. Patient reviews commonly note easy scheduling and accommodating staff. Use online portals to claim promotions quickly and the new patient chiropractic special.

On arrival, patients can expect a standard workflow: online booking, reception check-in, doctor consult, functional exam, and a recommended conservative plan. Clinics prioritize straightforward follow-up scheduling and practical guidance for home exercises and lifestyle adjustments.

| Package | Price | What’s Included | Best for |

|---|---|---|---|

| Starter package (example) | $88 (was $248) | Consult/exam, soft-tissue work, roller bed, review, one bonus modality | First-time patients seeking a full initial assessment |

| Professional consult + 2 bonuses | $58 | Targeted session plus two add-on modalities | Budget-conscious patients wanting targeted care |

| Standard session | Clinic-dependent | Tailored manual therapy, modality use, rehab plan | Continuing treatment and rehabilitation |

| Comparative benefit | N/A | Lower procedural risk; avoids surgery or injections when suitable | Those who want conservative options first |

Safety, Results & Realistic Expectations

Chirotherapy in Singapore rests on a mix of clinical studies and local clinic outcomes that support conservative care as both effective and safe. Readers often ask about safety evidence for chiropractic when comparing conservative choices to invasive care. Research and clinic reports highlight that targeted manual care, decompression, low level laser therapy and shockwave treatments can reduce pain and support tissue healing while minimizing risks related to surgery and chronic medication use.

Results depend on diagnosis and adherence. Singapore conservative outcomes typically show faster relief for acute strains and steady gains over weeks in chronic cases. Some patients notice change after a handful of visits. Other cases, such as degenerative disc disease, commonly follow a 2–4 month program. Adherence to home exercises and lifestyle advice has a clear impact on speed and durability of recovery.

Clinics follow structured assessments before any hands-on care. A typical pathway includes history-taking, functional tests and imaging review when needed. This approach supports safe, individualized plans and helps manage expectations about what a chiropractic session includes. Sessions often mix adjustments, soft-tissue, decompression and devices tailored to the diagnosis.

Safety protocols emphasize careful screening and conservative progressions. Pediatric and prenatal adjustments receive specific modifications to respect developmental needs. Reported adverse events are uncommon and modest when practitioners follow guidelines and modify techniques for higher-risk patients.

Common complementary therapies used alongside manual care enhance results. These include structured homework, supervised rehabilitation, therapeutic massage, and targeted modalities such as the Super Inductive System, radial shockwave and cold laser. Evidence shows such combinations improve pain control, reduce inflammation and restore function more reliably than single-modality approaches.

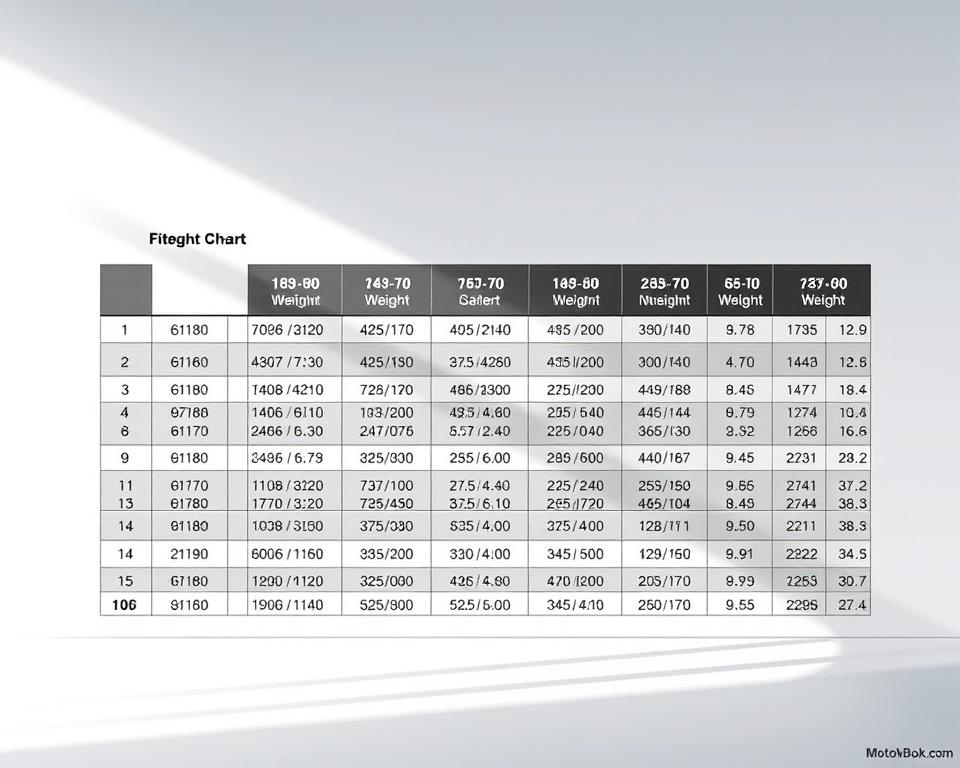

| Aspect | Typical Timeline | Likely Benefits | Risk Level |

|---|---|---|---|

| Acute muscle strain | about 1–4 weeks | Rapid pain relief, restored range of motion | Low |

| Radicular pain / sciatica | 4–12 weeks | Reduced nerve pain, improved function | Low–moderate by case |

| Degenerative changes | 2–4 months or longer | Slower symptom control, improved stability | Low when individualized |

| Pediatric and prenatal care | Stage-specific schedule | Comfort, function support | Very low with specialist techniques |

When preparing for your first visits, know that clinics will clarify aims, methods and timelines. Asking about safety evidence and conservative therapy outcomes Singapore ensures plans reflect your goals. Clear communication about symptoms, activity levels and prior treatments improves the quality of care you receive and sets realistic session-by-session expectations.

Wrapping Up

Elite Spine Centres offers a clear, patient-focused pathway for those seeking conservative spine care in Singapore. Their Functional Correction Method pairs hands-on chirotherapy with technologies like spinal decompression, Low Level Laser Therapy, Radial Shockwave Therapy, and the Super Inductive System. The aim is to treat root causes, not just symptoms, while limiting the need for surgery or chronic meds.

Care plans focus on evaluation, research-informed care, and structured rehab. Patients receive practical education and home exercises to support recovery and limit recurrence. This combined approach supports sustainable outcomes and faster return to daily activities.

For readers evaluating options, the takeaway on Chirotherapy Singapore is that Elite Spine Centres represents a modern, non-surgical care model. Current offers and simple booking make it easy for Singapore residents to explore conservative spinal care Singapore and learn how tailored programs can address individual needs.